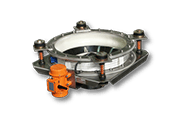

Visam Vibrators and Flow Equipments

Vibration motors, which operate via an electric motor or a pneumatic energy source, can be used for many different purposes. Vibration motors, i.e. vehicles that generate vibrations, are used in processes such as transportation, screening and classification of materials. Visam's vibration motors, which are manufactured in various sizes and design, meet the industry's requirements as reliable and durable equipment.

Features of Visam Vibration Motor

Visam's industrial vibration motors can easily handle intensive workloads with their high vibration power. The outstanding features of Visam vibration motors are as follows:- They have an adjustable vibration frequency, so they can easily adapt to different applications,

- They are durable equipment that can work in all harsh industrial conditions, including water, dust, impact or abrasion,

- The maintenance requirements are low, thus helping to reduce maintenance costs.

Where is the Visam Vibration Motor Used?

Visam's vibration motors can be used in various applications in many different areas. It is often used in the transportation and classification of materials, particularly in the mining industry. It is also used in the food industry for sieving, mixing and transporting food. Processes such as the transportation of building materials and the compaction of concrete can also be carried out using vibration motors. They can be used to test the shelf life of various products and for quality control. Visam's vibration machines are customizable equipment. In other words, a vibration motor can be manufactured for a specific application in any sector. For this, it is of course necessary to work with a reliable and competent brand.What are the advantages of using a vibration motor?

Vibration motors contribute significantly to increasing work efficiency due to their high vibration power. The advantages of using a vibration motor for companies are as follows:- It helps to speed up production processes by ensuring even transportation and feeding of materials,

- Classifying materials by size and texture to optimize material handling processes,

- It enables the atomization and feeding of liquid or powdered materials at a specific rate in processes that require precise dosing,

- As the vibration power is adjustable, it can be integrated into various applications,

- contributes to cost reduction as maintenance requirements are low,

- Despite their high performance, they have low energy consumption, which reduces energy costs,

- They can be counted among the environmentally friendly equipment, as they consume little energy and produce little waste.