Vibramod Vibrators and Flow Equipments

The vibration motor is one of the most effective equipment that help in reducing labor costs, increasing work efficiency and speeding up business processes. This explains its active use in many different sectors today. Vibramod is considered one of the best and most reliable brands in the production of vibration motors.

What is a Vibration Motor?

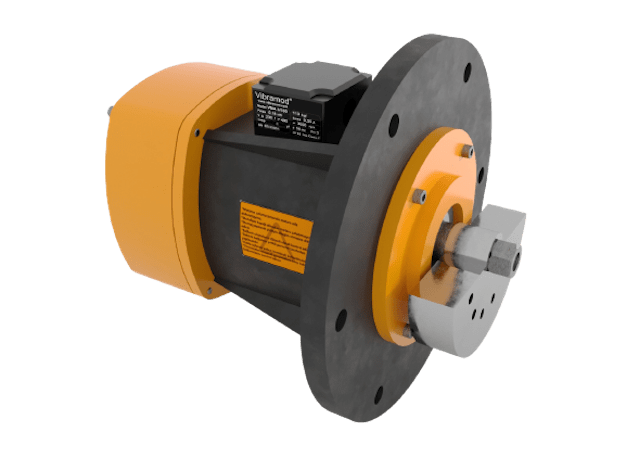

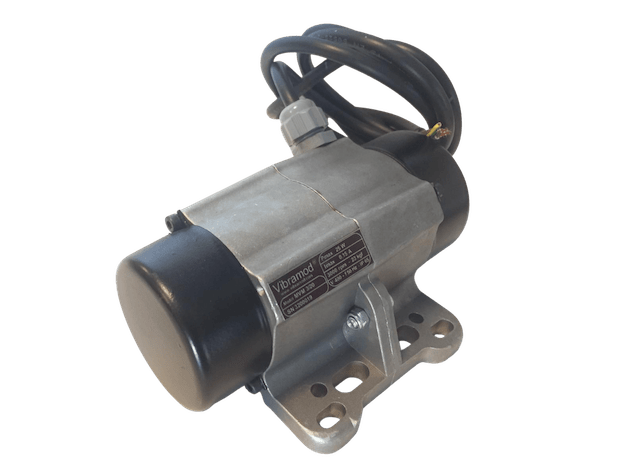

A vibrator motor is a device that uses vibrational motion to transport, feed or classify materials in various industrial applications. Vibration motors contain counterweights and the vibration is caused by the cyclic movement of the motor. The counterweights cause a disturbance in the balance, which causes engine movements to vibrate. The movements generated by the motor vary depending on the connection type. In addition to the micro vibration motors that can be used in various applications, Vibramod has also developed industrial vibration motors in the VMG, VMF and VMA series that can be used in various industries. As each of these motors has a customizable design, it can be adapted to different needs.Vibramod Vibration Motor Application Areas

The Vibramod vibration motor can be used for various purposes such as screening, placing, feeding and packaging in many different sectors. These systems, which increase productivity and work efficiency, are mainly used in the construction and mining industries. Vibration motors are also used in agriculture, in mills, in chimneys of air purification and thermal power plants, in the chemical industry, in packaging machines, in the ceramics industry, in the food industry, in recycling machines, in the building and construction industry, in mining and quarries, in the wood, glass and paper industries and in automatic selection and classification machines. Vibration motors can be manufactured in different sizes and characteristics depending on your requirements. All you need to do is identify your needs and work with a reliable brand that manufactures vibration motors.Advantages of the Vibramod Vibration Motor

Vibramod vibration motors are the most functional equipment that can be used in material transportation and feeding processes. The main advantages of these equipment can be listed as follows:- Provides much higher energy efficiency compared to drive systems,

- Maintenance requirements are low and servicing is simple, reducing maintenance costs,

- They are durable enough to adapt to harsh industrial conditions,

- They can be easily integrated into a variety of applications,

- Vibration control can be provided,

- It poses no risk to occupational safety.