Oli Vibrators and Flow Equipments

The Oli vibrator, widely used especially in heavy industry and manufacturing, is an aid for the transportation, classification or feeding of materials. These equipment, which generate a high centrifugal force, increase work efficiency. This type of equipment, which can be customized according to needs and applications, can be easily integrated into all sectors, from mining to construction, from recycling to the food industry. Oli's vibration motors, which can be equipped with functions tailored to your needs, help you save time and labor while increasing work efficiency.

What is a Vibration Motor? What Does It Do?

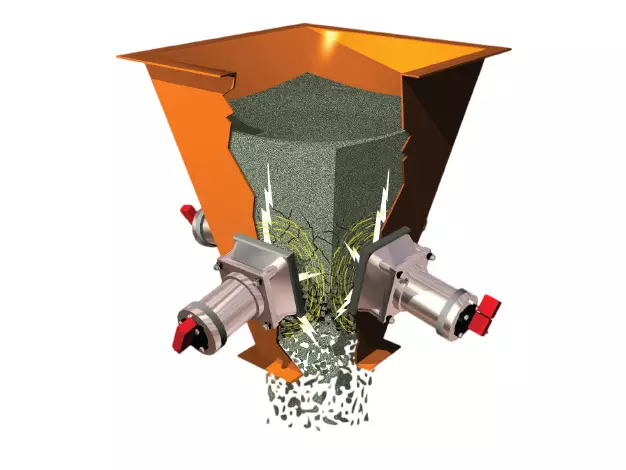

Vibration motors are equipment that facilitate and speed up the transportation, classification and processing of materials. The vibrations generated by vibratory motors allow materials to be moved, compacted, sieved or transported from one place to another. This helps to make work much more orderly and efficient. Vibration motors can be divided into two different categories; electric and pneumatic motors.Electric Vibration Motors

Vibration motors that work with electrical energy are usually connected to an alternating current (AC) and a direct current (DC) source. These types of vibration motors contain a number of mechanical and magnetic parts. These parts interact with each other and create a mechanical vibration. The vibration is usually generated by an unbalanced (eccentric) rotating shaft or by vibrating weights. The electric vibration motors are manufactured in different sizes and designs and can be adapted to the different needs of different industries. They are most commonly used in mobile feeding systems. They can also be used in construction machinery such as vibratory plates or concrete compactors.Pneumatic Vibration Motors

Pneumatic vibration motors, which work with compressed air, generate vibrations when a diaphragm or piston moves inside the motor. The most common applications of pneumatic vibration motors are vibrating material conveyor belts, increasing material flow in hoppers, classifying materials, feeding materials and preventing clogging. Pneumatic vibration motors contribute to many issues, from improving material flow to preventing blockages, from industrial cleaning processes to increasing work efficiency. Oli vibration motors can be used in many industries with maximum efficiency, from mining to building material production, from food production to chemistry.Advantages of Oli Vibration Motors

The main advantage of Oli vibration motors is that they make a high contribution to work efficiency. Oli vibration motors are designed with the needs of the equipment in mind and manufactured with maximum durability. Other outstanding advantages of Oli vibration motors can be listed as follows:- They can be easily used in the highest density applications,

- Time saving,

- It has a low noise level, even when performing at maximum power,

- It creates work safety as it reduces the force to be applied by the personnel,

- As it is manufactured according to international standards, it meets all requirements, even in the most difficult environments.

- It prevents work interruptions due to machine problems,

- Designed to meet direct requirements.