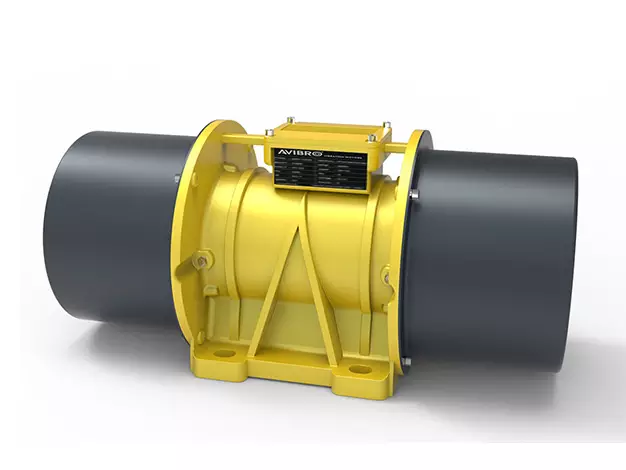

Avibro Vibrators and Flow Equipments

Avibro vibration motors are commonly used equipment to increase work efficiency in various sectors, minimize labor and integrate with various industrial equipment. They have a robust structure and a long service life. They are used in many different industries, from the food industry to mining, from building materials production to chemicals.

What is a Vibration Motor?

A vibration motor is a device that generates mechanical vibrations electrically or pneumatically. It is used in industry and heavy industry to transport, classify and feed materials or to remove blockages. It helps to reduce labor and increase work efficiency. They can be manufactured with different characteristics in terms of design, size and operating principles. It is possible to customize them for different sectors and needs. The industrial vibration motors manufactured by Avibro have a 3-phase input voltage. However, they can also be manufactured in special voltage or frequency ranges on request. In addition, all Avibro industrial vibration motors are suitable for use with variable frequency drives.Features of Avibro Industrial Vibration Motor

The industrial vibration motors developed by Avibro meet the requirements of companies operating in various industries. The outstanding features of the vibration motors developed by Avibro are:- The amount and intensity of vibration of industrial vibration motors that produce high vibration levels can vary depending on the power and design of the device. Avibro's industrial vibration motors can be manufactured in the desired power and intensity.

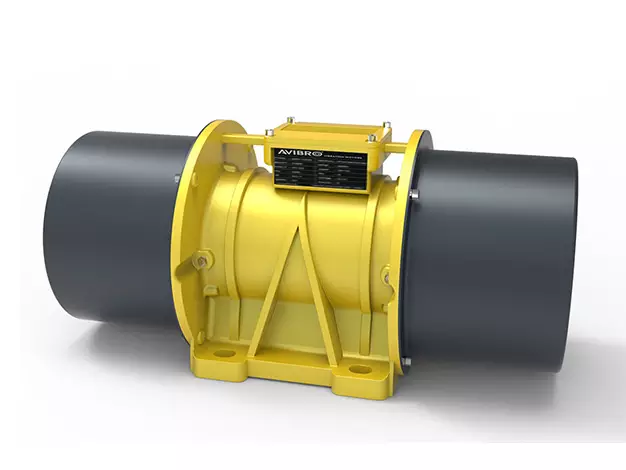

- They offer different power options so that the engine can be selected with a power to suit the requirements.

- They can be operated with alternating current (AC) or direct current (DC).

- They are made from durable materials that can withstand harsh working conditions, impact, abrasion and high temperatures.

- The fact that they can be manufactured in different sizes and designs makes it possible to meet different requirements.

- The vibration intensity of the manufactured vibration motors can be adjusted to achieve an operating performance that meets the requirements of the application.

- They can be easily integrated into industrial equipment. They can be easily mounted via flanges or mounting holes.

- As they have low maintenance requirements, they save money and are durable thanks to their robust structure.

- They can be integrated into various industrial equipment used in industry and commerce.

Where is the Avibro Industrial Vibration Motor Used?

Avibro industrial vibration motors can be used in all sectors, as their structure allows them to be integrated into any sector and maximize work efficiency. Some of the areas where industrial vibration motors are commonly used are:- Material transportation conveyors,

- Vibrating screens,

- Hoppers that allow the accumulation and storage of materials,

- Surface cleaning equipment,

- Machines for food production.