Screw Conveyors

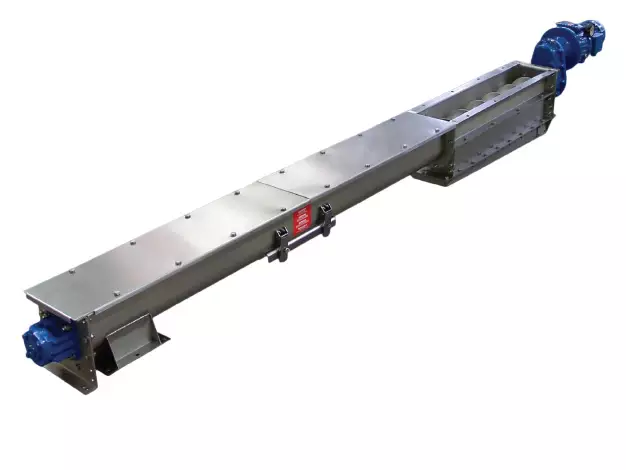

The screw conveyor, which is actively used in many sectors, is a mechanism that allows the materials to be transported in solid, liquid, powder or granular form through a helical screw called a helix. The screw conveyor system, which accompanies the modern age of industry, successfully carries out the transportation process in all facilities and areas where production takes place. Screw conveyor systems are differentiated according to their areas of application.

What is a Screw Conveyor?

What is the screw conveyor, which is characterized by its frequent use in industrial areas? The screw conveyor is used to transport and feed solid, liquid and powdery materials. The mechanism of the screw conveyor works on a practical basis and transfers the material flow effortlessly from point A to point B. There are differences in design depending on the area of application. The operating principles can change. For this reason, there are different types of screw conveyors. In general, specific features such as spiral structure, diameter, inlet and outlet structure and motor power determine the choice of mechanism. It is desirable that the mechanism used in the application areas is durable.What is a Screw Conveyor Used for?

The manufacture of the system, which is used in industrial sectors such as the food industry, chemical industry, construction, etc., is designed and manufactured according to the needs of standard or industrial plants. It ensures that material transportation in these areas is carried out smoothly and safely within the ideal framework. Screw conveyors transport many products such as cement, coal, ash, marble powder, polyethylene, plastic, flour, sugar, salt, coffee, spices and soda. Vordes increases the efficiency and safety of the systems with standardized elements that enable advanced capacity calculation of the screw conveyors. The mechanisms, that perform the transfer work with their advanced features, serve as feeders, carriers, dosers and accelerators. These tasks run in parallel with the screw conveyor blade, engine power and the capacity of the conveyor. Vordes plays a role in the successful transfer of any material, from food waste to municipal solid waste, with different conveying units depending on their liquid, powder, solid or granular structure.Types of Screw Conveyor

Tubular Screw: It is known as a tubular spiral with its tubular design and operating principle. It transports the material by guiding it through its tubular body with the rotating screw carrier in its design.

U/V trough screw: The U or V-trough screw is made of carbon steel or stainless steel and is used for the transportation of granular products. The application and maintenance of the U or V type system is practical.

Stainless (steel) Screw: The stainless steel screw, used in the cosmetics, food and pharmaceutical industries, transports sensitive materials safely and hygienically.

Multi-Inlet Screw: This is used when not just one material but several materials need to be conveyed. The number of inlets and outlets is increased and ensures systematic transfer.

Multi-Outlet Screw: The screws with several outlets, which are equipped with valves and slides, convey the material to more than one location at the same time or in a specific sequence.

Dosing & Micro Dosing Screw: The dosing screw makes it possible to adjust the quantity and speed of material transfer thanks to the feeding screw shaft and facilitates operation. The micro- dosing screw provides the required precision for applications requiring minimal dosing.

Cement Screw: Used in cement silos. Concrete and liquid materials in the silos of construction chemical centers are conveyed by these screws into the concrete mixer or weigher.

Tubular Screw: It is known as a tubular spiral with its tubular design and operating principle. It transports the material by guiding it through its tubular body with the rotating screw carrier in its design.

U/V trough screw: The U or V-trough screw is made of carbon steel or stainless steel and is used for the transportation of granular products. The application and maintenance of the U or V type system is practical.

Stainless (steel) Screw: The stainless steel screw, used in the cosmetics, food and pharmaceutical industries, transports sensitive materials safely and hygienically.

Multi-Inlet Screw: This is used when not just one material but several materials need to be conveyed. The number of inlets and outlets is increased and ensures systematic transfer.

Multi-Outlet Screw: The screws with several outlets, which are equipped with valves and slides, convey the material to more than one location at the same time or in a specific sequence.

Dosing & Micro Dosing Screw: The dosing screw makes it possible to adjust the quantity and speed of material transfer thanks to the feeding screw shaft and facilitates operation. The micro- dosing screw provides the required precision for applications requiring minimal dosing.

Cement Screw: Used in cement silos. Concrete and liquid materials in the silos of construction chemical centers are conveyed by these screws into the concrete mixer or weigher.

Screw Conveyor Usage Areas

The product group guarantees the safety of high-risk materials by ensuring that the materials are transported under high hygienic conditions and that the risks during transfer are minimized. It handles the transfer of materials that need to be mixed or dosed in specific quantities. These are the areas in which high-performance transfer mechanisms are used;- Power stations

- Iron and steel factories

- Food processing plants

- Cement plants

- Chemical industry

- Flour factories

- Agriculture

- Paper industry

Advantages of Screw Conveyor

The advantages of using screw conveyor systems are as follows;

The advantages of using screw conveyor systems are as follows;

- They minimize risks and ensure safe transport.

- It ensures that everything is systematic.

- It ensures hygienic transfer in the food industry.

- It balances the proportions and performs the mixing perfectly.

- Adjusts the dosage during feeding operations.

- It is easy to assemble and disassemble and its minimalist design makes it very practical.

- It can be used for transporting materials at high temperatures.

- Can be designed specifically for your needs. Particularly suitable for modular production.

Things to Consider When Choosing a Screw Conveyor

Nowadays, the areas of application for such conveyors are very diverse. In these areas, screw conveyors increase work efficiency and ensure time management. So "what should be considered when choosing a screw conveyor?" Here are the details; Screw conveyor price directly affects the purchasing decision. You should pay attention to the price performance comparison.

- The price of the screw conveyor has a direct impact on the purchase decision. You should pay attention to the price-performance comparison.

- It is necessary to scrutinize the carrying capacity of the conveyor mechanism to be purchased. Screw conveyors have different diameters and conveying capacities. A capacity calculation should be carried out to ensure efficiency.

- The right device must be selected depending on the material to be transported. A separate conveyor can be used for food and chemicals. The material to be conveyed must be taken into account.

- Stainless materials offer a long service life. Care should be taken to ensure that the material does not rust and is easy to maintain. More compact products are preferable to bulky products.