Rotary Valves

Advanced high-end equipment is used in almost all sectors, such as construction chemicals, ceramics and construction, micronized mining, agriculture, tea, pure water and waste water plants. The rotary valve is one of these equipment. The rotary valves, which have different types depending on the area of application, are referred to by many different names on the market. So what is a rotary valve, how does it work and what types of valves are there?

What is Rotary Valve?

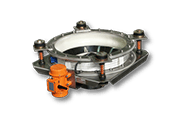

A rotary valve is a component that enables the discharge of granular or powdered material from dust collectors such as silos and controls its flow. This component is generally used to direct the material under the silo or bunker into the pneumatic conveying line in a controlled manner. It is an important part of pneumatic conveying systems to ensure the flow of material through the silo-bunker cyclone. Also known as a rotary valve or airlock. It has a similar logic to the structure of pneumatic or air conveying systems. Their names may vary depending on the application. Terms such as star lock, rotary valve, cellular wheel lock, star lock, air lock, cellular wheel lock and Eclus are used for the rotary valve. The rotary valve is made of carbon steel or cast iron. The airlock is used to control the flow of fly ash or powder and granules through silos and bunkers to ensure a stable flow. Used in many sectors, such as the iron and steel industry and the ready-mixed concrete sector, the rotary valve is the most effective equipment that can be used for the transportation of powder and granules. At Vordes Engineering you can purchase rotary valves as well as other equipment such as pneumatic vibrators.How Does the Rotary Valve Work?

It is possible to explain the question of how the rotary valve works, which is an important component in the conveying of powder and granules, can be explained in its simplest form as follows: The operating principle of the rotary valve is indeed very simple. In this wear-resistant equipment, solid liquids are conveyed downwards by gravity, preventing air from flowing in both directions through the rotor channels. In this way, both separation and mixing processes are carried out. In addition, this type of rotary valve equipment can separate during mixing. All equipment such as rotary valves or screw conveyors manufactured with the quality of Vordes Engineering and Wam Group are wear-resistant.

It is possible to explain the question of how the rotary valve works, which is an important component in the conveying of powder and granules, can be explained in its simplest form as follows: The operating principle of the rotary valve is indeed very simple. In this wear-resistant equipment, solid liquids are conveyed downwards by gravity, preventing air from flowing in both directions through the rotor channels. In this way, both separation and mixing processes are carried out. In addition, this type of rotary valve equipment can separate during mixing. All equipment such as rotary valves or screw conveyors manufactured with the quality of Vordes Engineering and Wam Group are wear-resistant.

What are the types of Rotary Valves?

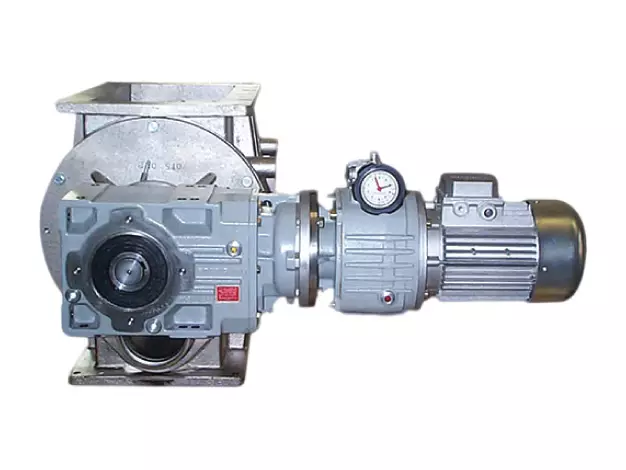

Pneumatic rotary valves are manufactured with different features depending on the application. The rotary valves that are guaranteed by Vordes Engineering have a carbon steel and stainless steel housing, inclined V-shaped cross-sections, a horizontally mounted rotor, a drive unit and a housing cover. The main advantages of the rotary valves are as follows:

Pneumatic rotary valves are manufactured with different features depending on the application. The rotary valves that are guaranteed by Vordes Engineering have a carbon steel and stainless steel housing, inclined V-shaped cross-sections, a horizontally mounted rotor, a drive unit and a housing cover. The main advantages of the rotary valves are as follows:

- It has standard flanges, making it compatible with all other Wam Group equipment.

- It has a robust, compact design.

- Easy access to all internal mechanical parts is possible.