Pipe Connections

What Do Pipe Connections Do?

Pipe connections, which are divided into different categories, are used to connect pipes in a system for the most common use. Completing any system and ensuring that the fluid that passes through it is transferred to other elements without leakage is only possible through the use of Pipe Connections . At this stage, various features such as the shape, size and angle of the equipment to be connected also influence the type of fitting used. Other basic purposes of using fittings include controlling the fluid, maintaining system functionality and aligning the system in the desired direction and inclination.How Do Pipe Connections Work?

Coupling models used to connect different types of parts are quite diverse, so the answers to questions like "What do Pipe Connections do?" and "How do pipe connections work?" may vary depending on the preferred equipment. Pipe fitting models which allow pipe installations to rotate and maneuver at an angle help to ensure uninterrupted flow throughout the installation. Internal, external or threaded types can also be used welded if required. In this way, they provide mechanical strength to the system by ensuring that pipes of different structures are connected together in the most durable and frictionless way possible, helping to keep the fluid inside flowing freely.

Where are Pipe Connections Used?

When asked what stainless steel Pipe Connections are, the first explanation that comes to mind can be given by the way they are used. In general, the answer to the question of where these products are used can be summarized as fixing points on pipelines, although this varies depending on the type of element used. Types of products that allow two pipes of different structures to be connected to each other have a very common area of use, as they prevent undesirable situations such as wear and corrosion. The main advantages of these elements, which are used in pipe systems in various buildings such as homes, offices, public areas and industrial buildings, can be summarized as follows:- Enables branching, maneuvering and connection of pipe installations.

- It is durable and flexible, ensuring a long service life for the system.

- Provides the advantage of easy cleaning and healthy use.

- It is suitable for various works such as installation, modification and replacement, and facilitates regular maintenance of the installations.

- It is used to prevent this problem in pipes where corrosion may occur and is also suitable for use in systems where acidic water is not present.

Pipe Connections Types

Depending on the area of application and intended use, the tube fitting types have different properties. In this regard, the prices of Pipe Connections on the market are quite diverse. The most commonly used types of fittings can be summarized as follows:- The reducer is used to connect two pipes of different diameters that are to be connected to each other by placing it between them. Thanks to its conical structure, it allows the fluid pressure to be varied.

- The Tee plays a role in branching the flow entering the pipeline and distributes the fluid in different directions. It is divided into different subtypes, with or without a passage, depending on the type of installation used.

- Elbow allows the pipe to be turned at the desired angle and in the desired direction, and due to this feature it ranks first among the most commonly used types of Pipe Connections. The WAM pipe bends in particular, with their 90 or 45 degree designs, are suitable for the safe operation of all installations.

- Flanges are generally used in high-pressure systems and ensure a tight connection between the parts. There are also Models available that are attached by welding.

- The nipple is a connecting element with or without threads, depending on the system in which it is used. It increases the durability of the systems by connecting them from the inside and is available in different versions.

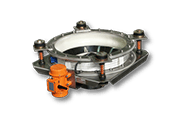

- The coupling allows the connection of two smooth pipe ends on the horizontal axis and is effective in increasing fluid velocity while being rigid.

Pipe Connections Models

The choice of the right pipe fitting depends on various parameters such as the material of the installation, the purpose and the general features. However, the most basic objectives are to make the entire system more durable by using such elements and to improve the health of the system by intervening early in any future maintenance and repair work. Therefore, products that play an important role in terms of equipment integrity, fluid flow, sealing and durability should be preferred from reliable brands. Failure to do so can create risks that negatively impact the safety and durability of the system. The most commonly used connection parts include:- WAM connection couplings are specialized parts used to securely connect pipe ends together and deliver fluid flow at a more stable rate. They add strength to the system and prevent leakage problems as they are combined with strong bolts or nuts.

- WAM elbows are innovative and short elbow models that are installed as connections to transport channels. Thanks to their special geometry, they allow access to dead areas in installations and extend the service life of the installation by minimizing wear in these areas.

- WAM filling pipes are flexible and wear-resistant connecting elements.