Oscillating Elements

What Do Oscillating Elements Do?

Oscillating elements, which are a type of suspension system, are devices that essentially absorb the vibrations in the system in which they are integrated. With their special rubber-based system, they increase the flexibility of the machines and maximize efficiency. For this reason, they are indispensable elements in the industrial sector. Another feature of the oscillating elements is the automatic clamping system. It adapts to the place of use and seasonal conditions, allowing flexible extension and shortening movements of the machines. In other words, oscillating elements increase the performance of the machines by extending their service life.Where are Oscillating Elements Used?

Oscillating elements, which are generally easy to adapt to standard machines but can also be designed in special dimensions on request, are widely used in systems such as:- Belt scrapers

- Press arms

- Conveyor belt

- Sieves

- Shock absorbers

- Tensioning the chain

- Belt tension

- Suspension

- Compressor

- Parking toy

- Motor vehicle

- Engine stand

- Vibration wedge

What Are The Advantages of Oscillating Elements?

Oscillating elements, which are used in most industrial machine systems, are products with high torsional strength. They are equipment that increases the performance of all machines to which they are attached, from shaker screens and feeders to tobacco processing machines. They give machines additional mobility by allowing them to reach oscillation levels that cannot be achieved under normal conditions. Oscillating elements are devices that are characterized by the following advantages:- They reduce wear by preventing metal-to-metal contact in machines.

- They do not allow lateral movements and contribute to pressure equalization.

- Increases machine efficiency and reduces machining time.

- Absorbs dangerous movements. This eliminates problems that could damage the system.

- Disorderly movements in systems connected with spring or rubber wedges are prevented by oscillating elements, eliminating the risk of noisy and unstable operation.

Oscillating Element Models

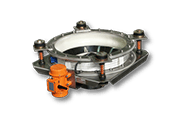

Oscillating elements can be divided into numerous sub-categories and adapted to the task at hand. Below are the oscillating element models that increase work efficiency in every respect and ensure sustainability in the company:OLI Oscillating Suspension

OLI oscillating suspensions support screw conveyor systems and provide a high level of insulation during operation. By controlling the displacement behavior, it makes it easier to trigger the oscillation in the desired direction. In this way, it helps to support the oscillating mass and prevents it from rolling sideways. The advantages are as follows:- High isolation

- Flexibility in operation

- Long service life

- Resonance damping