Loading Bellows

What is a Loading Bellows System?

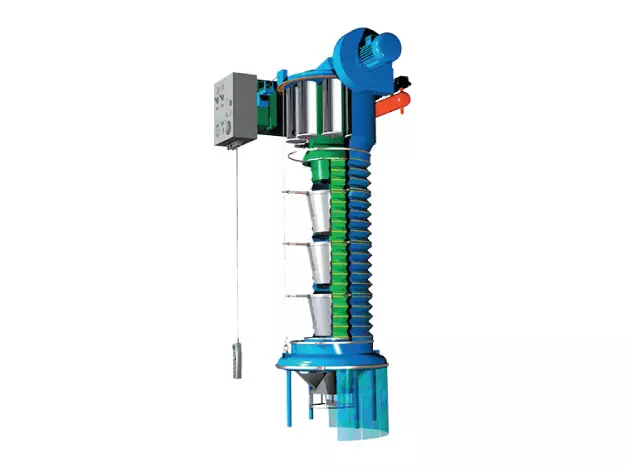

Loading bellows are advanced systems designed to load and unload raw materials and are supported by complementary accessories. This system, which is required in industrial plants, is used to direct the transfer of materials in a similar form to powders and granules to another location and to protect the health and cleanliness of the environment. The dense dust generated during material transfer is prevented by the loading and unloading system with bellows. This important equipment, which is a basic requirement for industrial life, is specially manufactured with advanced features and supporting accessories. The production of the system, which enables dust-free transfer service in this way, provides utilization functions.General Features of Loading Bellows

Bellows systems have the following features;- There is an additional system for dust separation. It collects the dust according to the type of raw material.

- Oil-repellent and moisture-retaining filter elements can be selected.

- A fan filter can be added if required.

- It has a special tip design (cone closing at the bottom) to prevent dust from spraying out.

- It is equipped with a sensor and supports efficiency.

Bellows Models

The loading bellows is available in various models. The features, areas of application and design of the individual models vary. Here are the types of loading systems; Closed volume bellows:: Used for loading silobas, closed ships with warehouses and closed containers. It has a sealing function with its flexible outlet mouth structure. During loading, the air inside the ship is sucked in by the system and the dust generated by the speed is captured.

Silo bellows for loading: Silo loading bellows meet the expectations for dust-free, fast and highly safe filling of raw materials in dry powder and granular form and prevent product loss.

Open environment loading bellows: These are systems that transfer raw materials in powder and granular form onto trucks, ships and similar vehicles, as well as into open areas. The most striking feature of the system is the automatic lifting and the flexible dust retention curtain.

Truck loading bellows: It transports dry powdered and granular materials safely and quickly onto open vehicles without generating dust. Truck loading bellows at the bunker discharge openings and at the outlets of systems such as pneumatic conveying systems and screw conveyors also prevent product loss.

Ship loading bellows: Bellows used to transfer granular and dry powders to the ship provide a safe and dust-free service. It is used at bunker unloading openings in port facilities, at the outlets of screw conveyors, elevators or pneumatic transport systems and handles the transfer of raw materials.

Bellows for the storage area: Storage systems that provide safe, fast and dust-free transfer to storage areas and raw material warehouses ensure that operations run smoothly as expected.

Closed volume bellows:: Used for loading silobas, closed ships with warehouses and closed containers. It has a sealing function with its flexible outlet mouth structure. During loading, the air inside the ship is sucked in by the system and the dust generated by the speed is captured.

Silo bellows for loading: Silo loading bellows meet the expectations for dust-free, fast and highly safe filling of raw materials in dry powder and granular form and prevent product loss.

Open environment loading bellows: These are systems that transfer raw materials in powder and granular form onto trucks, ships and similar vehicles, as well as into open areas. The most striking feature of the system is the automatic lifting and the flexible dust retention curtain.

Truck loading bellows: It transports dry powdered and granular materials safely and quickly onto open vehicles without generating dust. Truck loading bellows at the bunker discharge openings and at the outlets of systems such as pneumatic conveying systems and screw conveyors also prevent product loss.

Ship loading bellows: Bellows used to transfer granular and dry powders to the ship provide a safe and dust-free service. It is used at bunker unloading openings in port facilities, at the outlets of screw conveyors, elevators or pneumatic transport systems and handles the transfer of raw materials.

Bellows for the storage area: Storage systems that provide safe, fast and dust-free transfer to storage areas and raw material warehouses ensure that operations run smoothly as expected.

Loading Bellows Accessories

The bellows Models for the transportation of raw materials are designed for the use of accessories. These accessories or connections, which improve the system and increase its functionality, are as follows; Dust extraction: Prevents the spread of dust. There are different models depending on the structure of the powder. Dust extraction on the housing: The system collects the dust during the process and discharges it through filtration. The suction fan in the system draws in the dust and prevents product loss through the automatic cleaning function. Side-mounted dust extraction: Attached to the upper part of the main body of the loading bellows, the accessory prevents product loss through its automatic cleaning function. Independent dust extraction: In some cases, the dust extractors cannot be used in the blowers due to space limitations. In such cases, an air outlet pipe is used. Dust collection and dust extraction pipes are installed separately and the process is carried out. Centralized dust extraction: The centralized system, which facilitates the loading area in industrial plants, is used to collect dust at various points. Extraction is carried out by connecting air outlet ducts to dust extraction ducts. Automatic closing cone: In silo containers or closed wagon bellows, there is an automatic bottom closing cone. This cone closes the outlet opening under routine conditions. When the end of the bellows is placed at the entrance of the tanker during raw material transfer, it opens automatically and directs the flow. At the end of the process, it closes automatically. It does not allow dust to escape. Samplers: There are two types of samplers: manual, mechanical and automatic, which allow sampling during the flow of material during transfer. Both types are used to take samples for inspection prior to transfer. Level sensors: These systems are used in open and closed systems. The sensors give signals when the load reaches the highest level to prevent product loss. High temperature resistant bellows: For materials that are transported at high temperatures, such as fly ash, the equipment must also be suitable for this temperature. Heat-resistant bellows transport materials in powder and granular form up to 3000C. Atex-compatible bellows: These are systems with sensors against heat and gas formation, which are used when transporting flammable, explosive, highly flammable and combustible materials. Bellows suitable for food raw materials: Bellows for the transportation of raw materials in powder and granular form are preferred in the food industry. With its standard-compliant design, it ensures careful transportation. Loading Bellows Usage Areas

Loading Bellows Usage Areas

- Pharmaceutical industry

- Food industry

- Textile industry

- Industrial sector

- Production facility

- Construction industry

- Airport

- Marina

- Harbor

- Warehouse

Loading Bellows Usage Areas

Loading Bellows Usage Areas