Filters

Vordes offers complex filtration services with various brands such as Jet and Wam filters that support ventilation systems in industrial areas. At Vordes you will find filter unit solutions with branded alternatives that are compatible with various systems such as silos, spirals and tanks.

What Are Filter Units Used For?

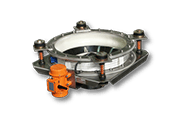

The answer to the question of what a Jet filter is, in view of its areas of application and effects, is briefly as follows: They are technical systems that provide clean air circulation by automatically removing and filtering the dust and smokes generated during production. There is a consensus in manufacturing plants about their necessity and they are accepted as essential equipment for airflow and efficiency. Dust or harmful air generated during production in industrial living spaces, transportation systems, production facilities and chemical areas is prevented and controlled with filters. Vordes offers four different types of filter units. Each filter differs in its usage features and ensures a clean air flow in the working areas. The Jet plus filter, for example, can be used in silos, bunkers, tanks and screw conveyors. Each unit, which has advanced features in terms of structure and design, has a certain standard and offers perfect solutions for its areas of application. In addition to the Jet filter, all other industrial ventilation filters are also used for air extraction. Strong dust, odor and smoke emissions occur during the production phase or during the operation of product transport systems. Specially developed devices such as Wam filters and ventilation supports automatically interrupt the bad air flow. Thanks to these filters, the harmful effects of the resulting dust and odors on nature and human life are prevented. Dust collection systems work efficiently and eliminate pollution in developing healthy work areas by controlling the airflow. The silo top filter is the perfect solution for areas where dust and smoke are continuously produced. Companies must take responsibility because their production activities cause pollution. For example, when products and materials are stored in silos, the installation of a ventilation system is not arbitrary, but a necessity. Silo top Jet filter systems can solve this necessity using technical methods. In this way, products such as food, chemicals and raw materials are stored in a clean air flow.Filter Unit Types

Ventilation systems are devices designed to prevent the spread of dust, odors and smoke in the environment. There are dozens of different filter models on the market and not just one filter that fulfills this function. The Jet pulse filter is one of these systems whose functionality balances the air flow in production areas. Looking at the operating principle of the Jet pulse filter, the pressure performance of the system is striking. With its strong suction power, the system removes gas, dust and smoke from storage areas such as bunkers and silos at high pressure, thus preventing the spread of dust.

Jet filter models differ depending on the area of application. The areas of application are determined by the production machinery and equipment of the facilities that conduct the sectors, and not by the sector. For example, the Jet pulse filter can be used where there are silos by placing it on the silo. Its operating principle is based on controlling the flow of powder during filling. The dust is filtered and systematically extracted.

Spiral silo top filters can be used everywhere, from the food industry to the construction industry. The dust that gets into the air during the transportation of cement and sand is removed with the help of silo filters. Raw materials such as cement, concrete, plaster and sand generate uncontrolled dust during discharge and filling. The main task of pulse filters is to prevent this dust accumulation and to keep air and workspace hygiene at an ideal level.

Ventilation systems are devices designed to prevent the spread of dust, odors and smoke in the environment. There are dozens of different filter models on the market and not just one filter that fulfills this function. The Jet pulse filter is one of these systems whose functionality balances the air flow in production areas. Looking at the operating principle of the Jet pulse filter, the pressure performance of the system is striking. With its strong suction power, the system removes gas, dust and smoke from storage areas such as bunkers and silos at high pressure, thus preventing the spread of dust.

Jet filter models differ depending on the area of application. The areas of application are determined by the production machinery and equipment of the facilities that conduct the sectors, and not by the sector. For example, the Jet pulse filter can be used where there are silos by placing it on the silo. Its operating principle is based on controlling the flow of powder during filling. The dust is filtered and systematically extracted.

Spiral silo top filters can be used everywhere, from the food industry to the construction industry. The dust that gets into the air during the transportation of cement and sand is removed with the help of silo filters. Raw materials such as cement, concrete, plaster and sand generate uncontrolled dust during discharge and filling. The main task of pulse filters is to prevent this dust accumulation and to keep air and workspace hygiene at an ideal level.

Features and Usage Areas of Filter Units

Jet pulse filter models have a structure that is compatible with today's systems. Adjustable, interchangeable structures and features increase functionality. The Wam filter series fulfills functional product expectations and clearly blocks bad air flows. Vordes emphasizes that the technical features of the equipment developed by the brands stand out. Before purchasing, you can explore all aspects of the equipment and analyze its usage areas. The Jet pulse filter systems from the Vordes range demonstrate solution-oriented approaches in the ideal of innovative industrial life and are appreciated for their performance. While the Jet filter is designed to prevent the spread of dirt, dust, smoke, chemicals and raw materials into the environment, it focuses on versatile use. For example, it provides this service when a bag filter is required by trapping the dust and dirt it attracts in the bag. Transport systems for products such as pulses, grain, raw materials, plastics, chemicals, etc. must always operate with the aim of not harming the environment or people. The machines and equipment in the systems are designed to be environmentally friendly and reliable. Both safety and continuity are efficiently guaranteed with the powder storage systems.

The variety of brands and models of filter systems adapts to the technical equipment in their areas of use. In this context, the answer to the question of what a Jet pulse filter is or where it is used can be sought. This is because it offers a more innovative and modern service compared to the classic filter systems in the industry. The removal of dust generated during storage and transportation is an innovative solution for the entire process. Food production plants, food warehouses, plastic production centers, dust - stone dust - gypsum dust - lime powder production plants provide the basis for keeping the ambient air at the ideal hygiene standard with dust removal systems.

The operating principle of spiral and silo filters is supported by features. The filters are easy to install and can be used in silo - spiral inlet - outlet sections. Improved models may be available on a product basis. For example, the cement silo top filter is preferred in production plants with similar function in different designs. Each device is designed to be environmentally friendly and not to harm people and natural life. They offer a sustainable service with spare parts support in case of parts failure. The Wam filter cartridge required for air extraction is easy to procure. The Wam filter is one of the well-known systems in the industry, its functionality is enhanced by many parts such as cartridges.