Dosing Units

What are Dosing Units?

In dosing processes, additives are added proportionally to specific amounts of raw materials, creating new substances that are suitable for different areas. Models with different properties are used to carry out such processes while maintaining precise ratios. The types of dosing units that have this quality play an important role in determining the quality or purity of the mixture. Therefore, the quality of the dosing unit, which is generally used for purposes such as reducing costs, increasing service life and maintaining purity, is very important.Types of Dosing Unit

Each dosing process is unique or requires the use of different equipment as a direct result of the differences in raw materials. For this reason, there are different variants on the market that are suitable for different purposes, and the prices of these dosing units also vary. Many parameters such as the process to be used, the type of substance to be used and the intended use have a strong influence on the choice of the respective unit. In chemical dosing, liquid or solid particles are introduced into the process at different intervals, with liquid substances generally being preferred. Since the accuracy of the frequency and quantity of raw material addition is also very important, the quality of the dosing is directly influenced by these factors. The devices in question are divided into sub-types and make it possible to automatically dose these types of chemicals of different kinds both in the desired quantity and in the desired way. In this respect, the variety of units used varies according to features such as raw material preference, quantity, addition method and pH booster.

Models of Dosing Units

Before using a product, one should be clear about the purpose of the dosing units and select the unit accordingly. WAM products, which are among the highest quality brands on the market, help to save the budget as they are advantageous both in terms of long-term use and durability. Among the types of devices manufactured for different requirements, the preferred WAM dispenser models can be listed as follows:MBF Micro Dosing Units

WAM's MBF micro feeders are particularly suitable for use with powdery or granular materials where there is a possibility of clogging and poor flow. The units, which are designed according to the modular system, offer the right solution for all types of user requirements. The MBF units, which can be manufactured with FDA approval on request, are suitable for foodstuffs. Key benefits include quick cleaning, easy access and simple maintenance.MBW Micro Dosing Units

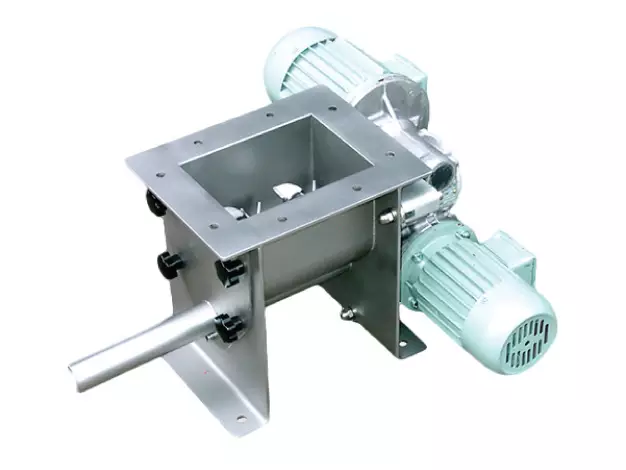

WAM's brand MBW microdosing devices are particularly suitable for the animal feed industry, plastics processing and the drinking water and water treatment industries. They are used for materials in these areas that have a medium flow rate and do not tend to jam. The product models, which are offered at the most competitive prices for micro feeders, are characterised by easy maintenance and cleaning.Loss Weight Screw Feedres

DCC screw feeders with empty weight measurement are models that are characterised by their precise measuring performance. Therefore, they offer a high quality dosing performance by providing an excellent advantage in ratio adjustment. The auger feeders, which are characterised by excellent working performance and easy operation, are also suitable for food applications and allow a free flow of material.What Are Dosing Units Used For?

The question of what dosing units are used for can be handled differently, as the different product types each allow different applications. In the most general sense, dosing units are machines that make it possible to combine various chemicals such as pH regulators, corrosion and limescale inhibitors with raw materials in the desired ratio.How Do Dosing Units Work?

These are units that dose regularly thanks to the spiral system inside the dosing units. The system can be operated as a volumetric or weight-decreasing system using a scale. The flow control can be precisely adjusted thanks to the variator or the frequency converter, it also allows automatic control and thus enables precise completion of the mixture.

Where are Dosing Units Used?

As the devices serve many industrial purposes, they can be used in different areas. These areas can be listed as follows:- Disinfection systems

- Flocculation systems

- Chlorine dosing systems

- Steam boilers

- Water and waste water systems

- Swimming pools

- Cooling towers

- Measuring and control devices

- Chemical storage tanks