What is a Pneumatic Vibrator?

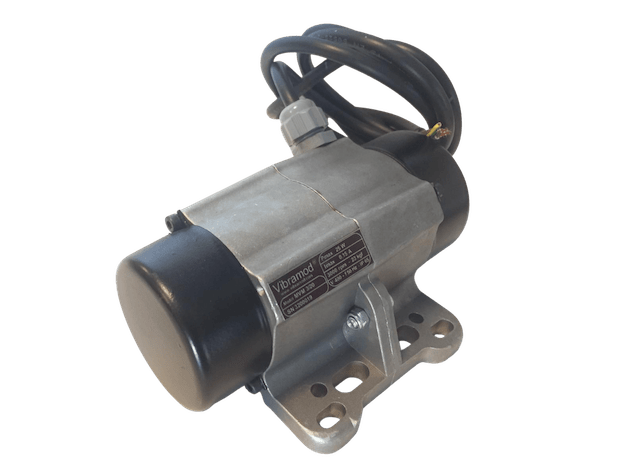

What is a pneumatic vibrator? How is it used? The pneumatic vibrator belongs to the family of power tools and is a tool that works with compressed air. It carries out drilling and breaking work in hard materials and floors such as concrete, tiles and asphalt. The system, which is often used on building sites and in road construction, works quickly like a drill with a percussive and repetitive working principle and delivers results in the area in which it is used in a short time.

Since the pneumatic vibrator is an electric hand tool, it works with powerful blows and delivers effective performance. Before pneumatic vibrators, these operations were carried out with sledgehammers, drills or sharp objects. This method, which required manpower, took a long time and did not produce effective results. With this developed system, hard materials are processed at high speed and in a short time. Long-lasting vibrators pave the way for working in different areas with different tips.

What is a Pneumatic Vibrator Used For?

The electro-pneumatic vibrator enables drilling, crushing and shredding of hard materials with compressed air. Electric vibrators, which serve as crushing and drilling tools, are used in a wide variety of areas, from hobby work to industry. They enable drilling or shredding of hard materials in many jobs, such as drilling, replacing tiles, replacing paving stones or rock removal, and require little effort.

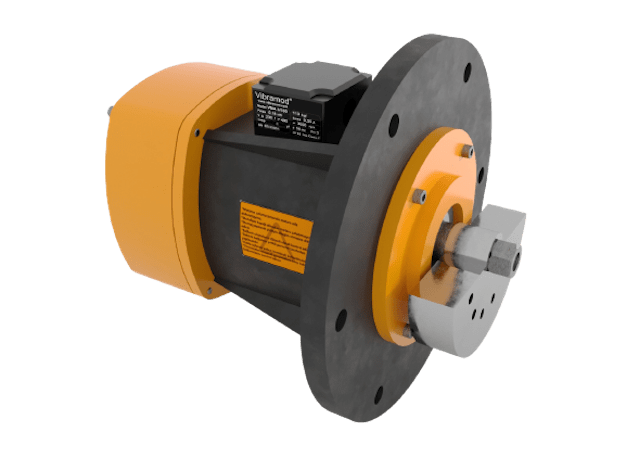

How does Pneumatic Vibrator Work?

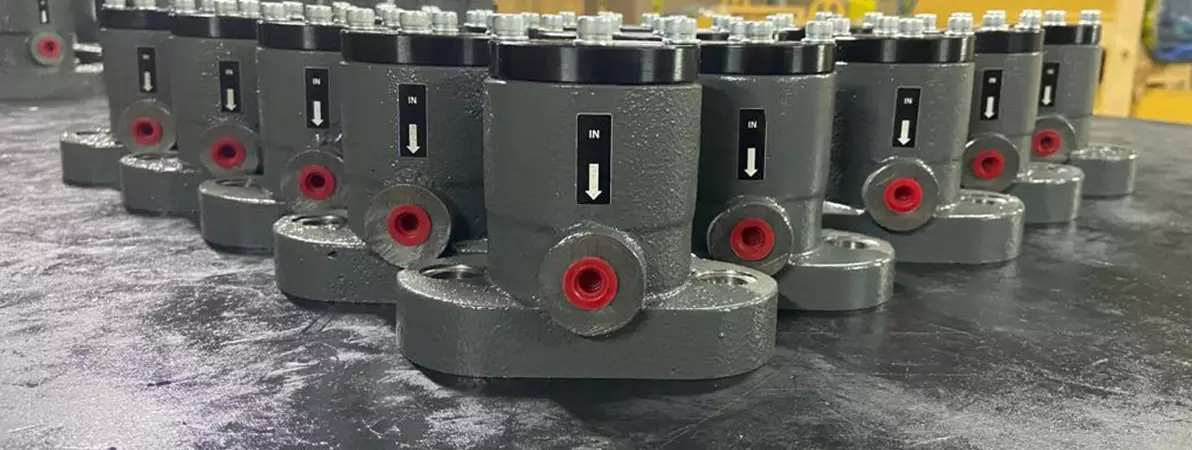

Pneumatic tools work with pulsating force and are supported by compressed air. The working principle of the hammer is based on compressed air. With the force generated by the compressed air, a cylindrical piston moves back and forth inside the cylinder and ensures that the tip of the tool works in a pulsating and continuous manner. The piston plays an important role in the operating principle of the system, which has its own production capacity. As the vibrator moves back and forth with the force of the press, it opens a safe exhaust port through which the compressed air in the cylinder can escape. The reciprocating structure means that every time the vibrator makes a blow to open a hole in the hard material, the mechanism is ready for the next new blow.

Pneumatic Vibrator Prices

The prices of vibrators, which have a wide range of applications, reduce working time and work efficiently, more than cover their performance. Prices for pneumatic vibrators have a price scale that varies depending on the product model and additional equipment. However, since this is a purely domestic production, the price range is wide. The tips of the vibrator and the vibrator itself can be sold as a set or individually and provide many years of quality performance.

Working Areas of Pneumatic Vibrator

Pneumatic cylinder vibrators are used in areas such as construction, industry, mining, geology, heavy industry, energy, plastics, chemicals, animal feed, food and environmental technology due to their high crushing and penetration properties. Pneumatic chip vibrators are preferably used in areas or situations where there is high humidity. Chip vibrators, also known as hydraulic hammers, are an effective aid for complex work. This is why pneumatic vibrators, chip vibrators and cylinder vibrators are used in work areas where advanced systems are available. Pneumatic tools ensure the fluidity of materials that are difficult to flow. These materials can sometimes be coal dust, sometimes sand or plaster. The pressure force of pneumatic tools regulates the flow speed even with sticky materials.